Custom Finishers is privately owned. We take a great deal of pride in consistently producing quality work and supporting our community. We believe in working closely with our customers and suppliers to achieve optimal results. You are always welcome to visit our plant!

We can help design display products from scratch, or re-imagine an existing design to optimize it for more cost-effective production.

Our 3D modeling capabilities offer a clear vision of your design. We also can reverse-engineer an existing design and create manufacturing drawings to ensure accuracy in final production. Solid Works, AutoCAD, Alpha Cam, Biesse Works, Cut-Rite and Illustrator files are all supported. We can make recommendations regarding manufacturability, including raw material and thickness, fasteners, edge treatments, surface decoration, etc. CFI is experienced at creating solid modeling from your CAD drawings.

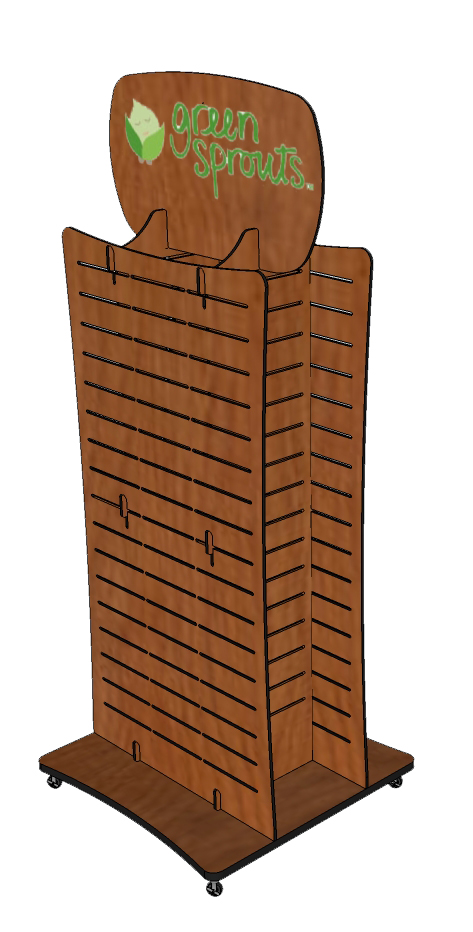

Laser Cut Composite Fiberboard and Hardboard Furniture Parts

Eagle Laser is our wholly owned, in-house, laser cutting / CNC machine service center started in 1989. Four high powered CO2 cutting systems run round-the-clock. Services include:

We process many types of wood based substrates along with steel, plastics, and glass.

Furniture, fixtures, point of purchase materials, and product handle boards are just a sample of the many areas where laser cut hardboard can make a significant impact.

LITHO AND LITHO SHEET LAMINATION

To achieve that champagne look with unbelievable definition while staying on a low budget, Custom Finishers uses litho paper laminated on hardboard and laser cut to your designers’ specifications.

CFI mounts printed litho sheets supplied by our customers. Most of the products we laminate are laser cut after mounting. The end product could be display headers, wall mounted signage, rigid boards for hard surface flooring or full-scale stand-up portraits. Our substrates are rigid and durable, with no die charges.

Coming soon

For over 30 years, CFI has enjoyed a strategic partnership with a local screen printer, cranfordsilkscreen.com. The company does excellent work. We sub-contract our graphics production to Cranford’s. Some customers deal directly with them.

CFI’s 50,000-square-foot facility has ample storage and distribution capacity for Just In Time Delivery to suit your purpose. We offer pack out and direct from factory drop shipments. We have storage capacity for large roll-outs, or seasonal products where large quantity shipments in a short period of time are required.

Order Fulfillment

CFI helps you hit deadlines by offering on-site order fulfillment solutions. Too maintain shipping cost efficiency we can ship them “knocked-down” and packed in custom cartons to provide the edge you need to win that bid. Understanding the importance of this, we know that this can be the final phase of any roll-out, reset, or primary use of all types of component packs needed.

Some services offered:

Our accurate, dependable supply-chain team has the flexibility to fit seamlessly into your distribution flow.

All purchased raw board is delivered mill-direct in full truckloads. Our materials come from the US, Canada, Brazil and Argentina. All are FSC Certified and CARB II compliant. MDF, HDF and hardboard (Masonite) ranging in thickness from 1/8 (3.0mm) to 1” (25mm) is stocked in a variety of sheet sizes.

We have a one-week turnaround time for simple cut, raw rectangles. For secondary processes including painted or wood grain, the time is two weeks. With fabrication and painting, the time is an additional three weeks. These are requested lead times, however we work very hard to satisfy your needs.